Overview of ZJHP Pneumatic Single Seat Regulating Valve

ZJHP series pneumatic thin film straight through single seat regulating valveAdopting a top guide structure and equipped with multiple spring actuators. It has the advantages of compact structure, light weight, sensitive action, streamlined fluid channels, low pressure drop loss, large valve capacity, accurate flow characteristics, and easy disassembly and assembly. Widely used for accurate control of gas, liquid and other media, process parameters such as pressure, flow rate, temperature, and liquid level are maintained at given values. Especially suitable for working environments where the pressure difference between the front and rear of the leakage star valve is not significant.

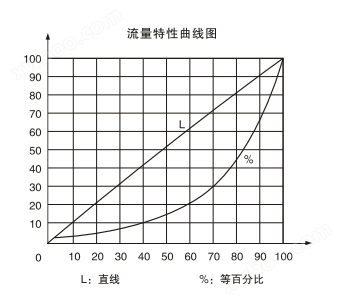

This series of products includes various types such as standard type, regulating shut-off valve, corrugated pipe sealing type, jacket insulation type, etc. The nominal pressure rating of the product includes PN10, 16, 40, and 64; The valve body diameter range is DN20~300. The applicable fluid temperature ranges from -196 ℃ to+560 ℃ in various grades. The leakage star standard has IV or VI level. The flow characteristics are linear or equal percentage. A variety of varieties and specifications are available for selection.

Characteristics of ZJHP Pneumatic Single Seat Regulating Valve

1. Top guided single seat regulating valve, compact structure, few components, easy to maintain.

2. The metal valve core is suitable for various working environments and meets the IV level leakage standard, while the soft seal structure valve core meets the VI level leakage standard.

3. The valve body is designed according to the principles of fluid mechanics as a low resistance flow channel with equal cross-section, increasing the rated flow coefficient by 30%. The adjustable range is large, with an inherent adjustable ratio of 50:1. The actuator adopts a multi spring structure, reducing the height by 30%. Reduce weight by 30%.

4. ZJHPW type bellows sealed regulating valve forms a complete seal for the moving valve stem, blocking fluid leakage. The ZJHPJ type regulating valve is equipped with an insulation jacket, which is used in situations where the fluid is prone to crystallization and solidification after cooling, causing blockage.

Common materials for main components

| name | material |

| Valve body and valve cover | ZG230-450、ZG0Cr18Ni9 |

| Valve core and seat | 0Cr18Ni9, 0Cr18Ni9+PTFE, 0Cr18Ni9+Stale |

| filler | PTFE、 Flexible graphite |

| corrugated tube | 0Cr18Ni9 |

| shim | Graphite wrapped gasket (V6590), toothed gasket |

| Membrane cover | A3、0Cr18Ni9 |

| corrugated diaphragm | Clamp reinforced nylon fabric nitrile rubber |

| spring | 60Si2Mn |

| Valve stem push rod | 0Cr18Ni9、2cr13 |

Main technical parameters of single seat valve

| Nominal Diameter | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||||||||

| Valve seat diameter mm | 10 | 12 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |||||||

| Rated kV | linear | 1.8 | 2.8 | 4.4 | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 | 1000 | 1600 | ||||||

| Equal percentage | 1.6 | 2.5 | 4.0 | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 900 | 1440 | |||||||

| Nominal pressure (MPa) | 1.6, 2.5, 4.0, 6.4, 10 | ||||||||||||||||||||||

| Travel distance (mm) | 16 | 25 | 40 | 60 | 100 | ||||||||||||||||||

| Effective area of thin film Ae (cm2) | 280 | 350 | 560 | 900 | 1400 | ||||||||||||||||||

| Signal range KPa | 20-100, 40-200, 80-240 | ||||||||||||||||||||||

| Gas source pressure MPa | 0.1--0.4 | ||||||||||||||||||||||

| Inherent flow characteristics | Linear, equal percentage, fast opening | ||||||||||||||||||||||

| Inherent adjustable ratio | 50:1 | ||||||||||||||||||||||

| Leakage level | Hard sealed Class IV and V; Soft seal VI | ||||||||||||||||||||||

| Flange size | Compliant with JB/79. (2) _94, HG20592_97, GB, ANSI, JIB, DIN and other standards | ||||||||||||||||||||||

| body material | WCB、304、316、WC6、 Titanium, nickel, Hastelloy, Monel, etc | ||||||||||||||||||||||

| Valve core material | 304, 316, 420, titanium, nickel, Hastelloy, Monel, etc | ||||||||||||||||||||||

| Working temperature ℃ | -40~+230 ℃ (normal temperature),+230~+450 ℃ (medium temperature),+450~+560 ℃ (high temperature), -40~-196 ℃ (low temperature) | ||||||||||||||||||||||

| Series type | Normal temperature type, medium temperature type, low temperature type. Bellows sealing type, jacket insulation type, adjustable cutting type | ||||||||||||||||||||||

Main performance indicators

| Serial Number | project | Standard type regulating valve | High temperature and low temperature regulating valves | ||||

| Without locator | Equipped with locator | Without locator | Equipped with locator | ||||

| 1 | Basic error (%) | ±5 | ±1 | ±15 | ±4 | ||

| 2 | Return difference<><td=''> | 3 | 1 | 10 | 3 | ||

| 3 | Four zones<><td=''> | 3 | 0.4 | 8 | 1 | ||

| 4 | Constant point deviation<><td=''> | air to open | Starting point | ±2.5 | ±1 | ±6 |

±2.5 |

| End | ±5 | ±15 | |||||

| air to close | Starting point | ±5 | ±15 | ||||

| End | ±2.5 | ±6 | |||||

| 5 | Rated travel deviation<><td=''> | ±2.5 | +2.5 | +6 | +2.5 | ||

Note: The performance of this product complies with GB/T4213-2008

Gas sealed (positive acting) metal seal type allowable differential pressure gaugeUnit: MPa

| Model of actuator | Spring range (KPa) | Gas source pressure (KPa) | Positioner (with/without) | Valve seat diameter dn (mm) | ||||||||||

| 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||

| ZHA-22 | 20-100 | 0.14 | deny | 0.95 | 0.61 | |||||||||

| belt | 2.55 | 1.63 | ||||||||||||

| 40-200 | 0.25 | belt | 3.34 | 2.14 | ||||||||||

| 80-240 | 0.4 | belt | 6.52 | 4.17 | ||||||||||

| ZHA-23 | 20-100 | 0.14 | deny | 0.49 | 0.32 | 0.20 | ||||||||

| belt | 1.31 | 0.84 | 0.54 | |||||||||||

| 40-200 | 0.25 | belt | 1.72 | 1.10 | 0.71 | |||||||||

| 80-240 | 0.4 | belt | 3.36 | 2.15 | 1.37 | |||||||||

| ZHA-34 | 20-100 | 0.14 | deny | 0.18 | 0.12 | 0.08 | ||||||||

| belt | 0.49 | 0.32 | 0.21 | |||||||||||

| 40-200 | 0.25 | belt | 0.65 | 0.43 | 0.27 | |||||||||

| 80-240 | 0.4 | belt | 1.26 | 0.83 | 0.53 | |||||||||

| ZHA-45 | 20-100 | 0.14 | deny | 0.09 | 0.06 | 0.03 | ||||||||

| belt | 0.23 | 0.16 | 0.09 | |||||||||||

| 40-200 | 0.25 | belt | 0.30 | 0.21 | 0.12 | |||||||||

| 80-240 | 0.4 | belt | 0.58 | 0.40 | 0.22 | |||||||||

Gas sealed (reactive) metal seal type allowable differential pressure gauge Unit: MPa

| Model of actuator | Spring range (KPa) | Gas source pressure (KPa) | Positioner (with/without) | Valve seat diameter dn (mm) | ||||||||||

| 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||

| ZHA-22 | 20-100 | 0.14 | With/Without | 0.95 | 0.61 | |||||||||

| 40-200 | 0.25 | belt | 2.55 | 1.63 | ||||||||||

| 80-240 | 0.28 | belt | 5.73 | 3.67 | ||||||||||

| ZHA-23 | 20-100 | 0.14 | With/Without | 0.49 | 0.32 | 0.20 | ||||||||

| 40-200 | 0.25 | belt | 1.31 | 0.84 | 0.54 | |||||||||

| 80-240 | 0.28 | belt | 2.95 | 1.89 | 1.21 | |||||||||

| ZHA-34 | 20-100 | 0.14 | With/Without | 0.18 | 0.12 | 0.08 | ||||||||

| 40-200 | 0.25 | belt | 0.49 | 0.32 | 0.21 | |||||||||

| 80-240 | 0.28 | belt | 1.11 | 0.73 | 0.47 | |||||||||

| ZHA-45 | 20-100 | 0.14 | With/Without | 0.09 | 0.06 | 0.03 | ||||||||

| 40-200 | 0.25 | belt | 0.23 | 0.16 | 0.09 | |||||||||

| 80-240 | 0.28 | belt | 0.52 | 0.36 | 0.20 | |||||||||

Gas sealed (reactive) metal seal type allowable differential pressure gauge Unit: MPa

| Model of actuator | Spring range (KPa) | Gas source pressure (KPa) | Positioner (with/without) | Valve seat diameter dn (mm) | ||||||||||

| 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||

| ZHA-22 | 20-100 | 0.14 | deny | 1.20 | 0.76 | |||||||||

| belt | 2.78 | 1.78 | ||||||||||||

| 40-200 | 0.25 | belt | 3.00 | 2.29 | ||||||||||

| 80-240 | 0.4 | belt | 3.00 | 3.00 | ||||||||||

| ZHA-23 | 20-100 | 0.14 | deny | 0.62 | 0.39 | 0.25 | ||||||||

| belt | 1.44 | 0.92 | 0.59 | |||||||||||

| 40-200 | 0.25 | belt | 1.85 | 1.18 | 0.76 | |||||||||

| 80-240 | 0.4 | belt | 3.00 | 2.23 | 1.42 | |||||||||

| ZHA-34 | 20-100 | 0.14 | deny | 0.23 | 0.15 | 0.10 | ||||||||

| belt | 0.54 | 0.36 | 0.23 | |||||||||||

| 40-200 | 0.25 | belt | 0.69 | 0.46 | 0.29 | |||||||||

| 80-240 | 0.4 | belt | 1.30 | 0.86 | 0.55 | |||||||||

| ZHA-45 | 20-100 | 0.14 | deny | 0.11 | 0.08 | 0.04 | ||||||||

| belt | 0.25 | 0.17 | 0.10 | |||||||||||

| 40-200 | 0.25 | belt | 0.32 | 0.22 | 0.13 | |||||||||

| 80-240 | 0.4 | belt | 0.60 | 0.42 | 0.23 | |||||||||

Gas closed (positive action) metal sealed type allowable differential pressure gauge Unit: MPa

| Model of actuator | Spring range (KPa) | Gas source pressure (KPa) | Positioner (with/without) | Valve seat diameter dn (mm) | ||||||||||

| 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | ||||

| ZHA-22 | 20-100 | 0.14 | With/Without | 1.19 | 0.76 | |||||||||

| 40-200 | 0.25 | belt | 2.78 | 1.78 | ||||||||||

| 80-240 | 0.28 | belt | 3.00 | 3.00 | ||||||||||

| ZHA-23 | 20-100 | 0.14 | With/Without | 0.62 | 0.39 | 0.25 | ||||||||

| 40-200 | 0.25 | belt | 1.44 | 0.92 | 0.59 | |||||||||

| 80-240 | 0.28 | belt | 3.00 | 1.97 | 1.26 | |||||||||

| ZHA-34 | 20-100 | 0.14 | With/Without | 0.23 | 0.15 | 0.10 | ||||||||

| 40-200 | 0.25 | belt | 0.54 | 0.36 | 0.23 | |||||||||

| 80-240 | 0.28 | belt | 1.15 | 0.76 | 0.49 | |||||||||

| ZHA-45 | 20-100 | 0.14 | With/Without | 0.11 | 0.07 | 0.04 | ||||||||

| 40-200 | 0.25 | belt | 0.25 | 0.17 | 0.10 | |||||||||

| 80-240 | 0.28 | belt | 0.54 | 0.37 | 0.21 | |||||||||

Note on allowable differential pressure gauge:

1. The packing material is PTFE

2. The flow direction of the medium is opposite to the direction in which the valve core closes

3. The leakage level of metal sealed type is IV level

4. Values are limited by nominal pressure, pressure, and temperature

5. When the sealing type P2 of the corrugated pipe is ≠ 0, it needs to be rechecked;

Dimensions and weight unit: mm

| Public diameter DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||||||||||||||||||

| L | PN16MPa | 187 | 184 | 200 | 222 | 254 | 276 | 298 | 352 | 410 | 451 | 600 | 673 | 737 | |||||||||||||||||

| PN16MPa | 194 | 197 | 210 | 235 | 267 | 292 | 317 | 368 | 425 | 473 | 600 | 708 | 775 | ||||||||||||||||||

| PN16MPa | 206 | 210 | 220 | 251 | 286 | 311 | 337 | 394 | 440 | 508 | 650 | 752 | 819 | ||||||||||||||||||

| A | 280 | 360 | 470 | 580 | |||||||||||||||||||||||||||

| H1 | PN16、40 | 53 | 58 | 68 | 73 | 80 | 90 | 98 | 108 | 108 | 140 | 168 | 225 | 245 | |||||||||||||||||

| PN16、64 | 63 | 68 | 75 | 83 | 88 | 100 | 105 | 125 | 125 | 170 | 203 | 260 | 280 | ||||||||||||||||||

| H2 | actuator | 280 | 310 | 395 | 525 | 725 | |||||||||||||||||||||||||

| H3 | High temperature heat sink type | 210 | 210 | 225 | 230 | 230 | 335 | 335 | 345 | 408 | 454 | 482 | 550 | 580 | |||||||||||||||||

| Bellows sealed type | 303 | 305 | 392 | 395 | 405 | 529 | 540 | 553 | 710 | 756 | 800 | 900 | 940 | ||||||||||||||||||

| H | Standard room temperature type | 400 | 420 | 450 | 455 | 460 | 610 | 622 | 640 | 780 | 870 | 890 | 1205 | 1235 | |||||||||||||||||

| Low temperature type | H3 | 750 | 900 | ||||||||||||||||||||||||||||

| H4 | 90 | 90 | 92 | 92 | 92 | 98 | 98 | 98 | 110 | 120 | 120 | 180 | 180 | ||||||||||||||||||

| D | 310 | 310 | 335 | 335 | 335 | 430 | 465 | 520 | 585 | 660 | 770 | 850 | 850 | ||||||||||||||||||

| Weight kg | PN16/40 | 20 | 22 | 25 | 32 | 38 | 62 | 67 | 83 | 132 | 160 | 245 | 350 | 470 | |||||||||||||||||

| N64/100 | 24 | 25 | 30 | 42 | 52 | 78 | 82 | 102 | 170 | 190 | 285 | 500 | 660 | ||||||||||||||||||

| Low temperature type PN16/40 | 40 | 48 | 52 | 60 | 68 | 90 | 105 | 143 | 210 | 282 | 315 | 580 | 800 | ||||||||||||||||||

| Low temperature type PN64/100 | 50 | 60 | 65 | 75 | 85 | 112 | 131 | 178 | 262 | 352 | 393 | 725 | 980 | ||||||||||||||||||

When placing an order, please fill out the "Specification Form" or indicate the following content:

1、 If the model has not been selected before placing the order, please provide us with your usage parameters

1. Nominal diameter and rated current coefficient Kv

2. Fluid properties (including nominal pressure, temperature, viscosity, or acidity/alkalinity)

3. Valve action form (gas closed or gas open)

4. Flow characteristics

5. Pressure before and after the valve

6. Valve body, wide core material

7. Input signal

8. Do you have any attachments? Please specify the attachment model so that we can make the correct selection for you.

2、 Special requirements

1. Special Inspection

2. Complete oil and water removal treatment;

3. Copper prohibition treatment;

4. Special interfaces and piping;

5. Used under vacuum conditions;

6. Specify coating color

7. Special media (gas, chlorine, nitrogen)

8. Use stainless steel connectors;

3、 If the design unit has already selected our company's product model, please place an order directly with our sales department based on the model

4、 When the application is very important or the pipeline is complex, please provide design drawings and detailed parameters, and our experts will review and control them for you.

pneumatic control valveInstallation precautions, please click here