Adopting fully automatic PID control, it has high precision and can save 30% electricity,

The three box equipment is divided into three parts: high temperature zone, low temperature zone, and testing zone. The test product is placed in the testing zone, and the temperature of the high or low temperature zone is flushed into the testing zone for impact. The test product is static.

※ Adopting a touch based graphical control interface, the operation tube is easy to operate.

※ The impact method applies the air path switching method to import the temperature into the testing area for conducting cold and hot impact tests.

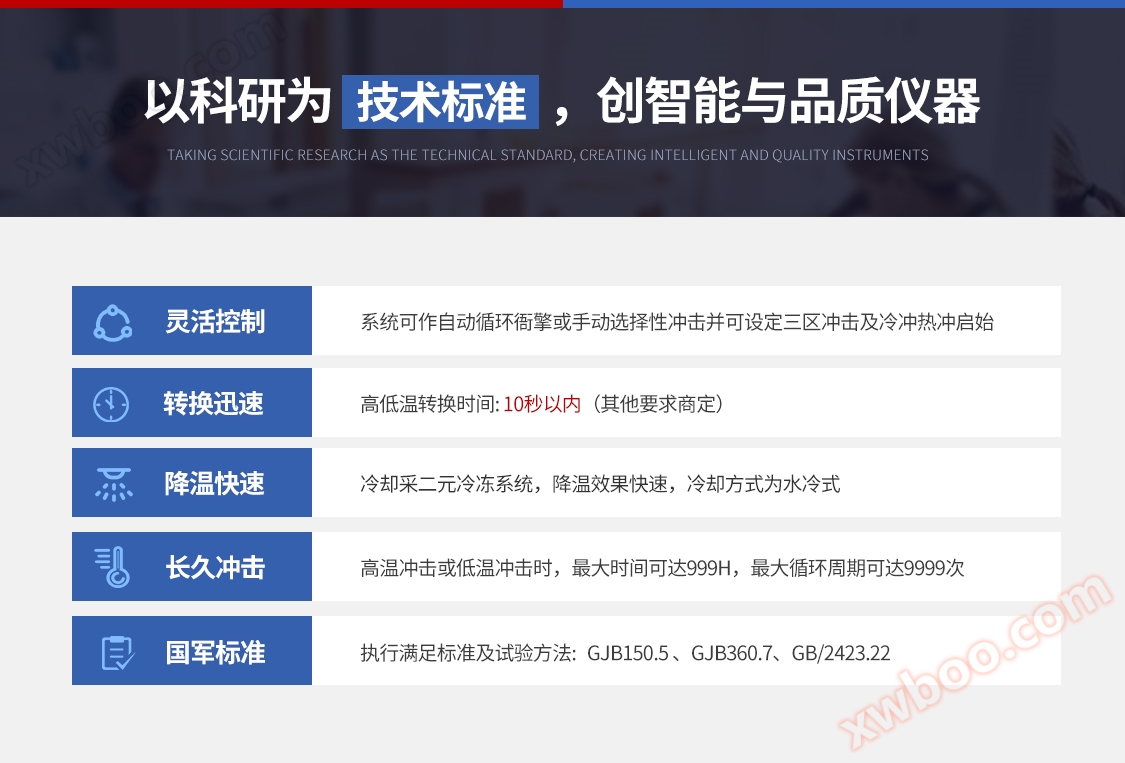

During high or low temperature impact, the maximum time can reach 999H and the maximum cycle period can reach 9999 times.

The system can be used for automatic cycling or manual selective impact, and can set the start of three zone impact, cold impact, and hot impact.

The cooling system adopts a binary freezing system, which has a fast cooling effect and is water-cooled.

Three boxes can be tested for impact at room temperature,

High and low temperature conversion time: within 10 seconds (other requirements to be agreed upon)

Implement standards and test methods that meet the requirements: GJB150.5 temperature shock test; GJB360.7 temperature shock test; GB/2423.22 Temperature Shock Test

model |

WBE-LR3D-1400L |

||

Internal dimensions WxDxH (cm) |

140 × 100 × 100 (or customizable) |

||

Laboratory temperature range ℃ |

150℃~ABC |

||

A -40 |

B -55 |

C-65 |

|

Heating temperature (heat storage area) ℃ |

60℃~200℃ |

||

Cooling temperature (cold storage zone) ℃ |

A:-10℃~ -55℃ B:- 10℃~ -70℃ C:- 10℃~ -75℃ |

||

Heating time (heat storage area) min |

RT~200 ℃ requires approximately ≤ 35 minutes |

||

Cooling time (cold storage zone) min |

A:+ 20~-55 ℃ takes about 60 minutes B:+20~-70 ℃ takes about ≤ 70 minutes C:+20~-75 ℃ takes about 85 minutes |

||

Environmental temperature for use |

Water cooling environment temperature requirement+5~+35 ℃ |

||

Temperature recovery time |

Within 5 minutes |

||

Exposure to high temperature for 30 minutes | |||

Low temperature exposure for 30 minutes | |||

temperature control accuracy |

±0.5℃ |

||

Uniformity |

±2.0℃ |

||

Internal and external materials |

Steel plate electrostatic spraying surface treatment or SUS 304 stainless steel |

||

Internal material |

SUS 304 stainless steel |

||

Insulation material |

High density polyurethane foam+glass wool |

||

control system |

7-inch touch screen, display in both Chinese and English, 120 sets of programs, 1200 segments, 99 full cycles, 99 partial cycles, temperature 0.1% of F.S ± 1digit, humidity 0.1% of F.S ± 1digit, temperature pt-100, humidity pt-100 or 5V DCV communication USB or RS485 (other communication to be negotiated) |

||

refrigerant |

R404/R23 (environmentally friendly refrigerant) |

||

Cooling system |

Semi closed two-stage compressor (water-cooled) |

||

Safety protection device |

1. Compressor overpressure, overheating, and overcurrent protection; 2. High pressure protection switch for refrigerant; 3. Fault alarm system; 4. Thermal storage, high temperature storage, cold storage, and low temperature protection; 5. Electronic alarm; 6. Water shortage alarm protection (water-cooled); 7. Non fuse switch; 8. Power phase sequence protection; 9. Temperature protection of the test chamber |

||

Standard accessories |

Two sample racks, measuring hole diameter of 50mm * 1, power cord, instruction manual |

||

power supply |

AC380V 50HZ three-phase four wire+ground wire |

||

controller |

South Korean TECH Sanyuan/Taitong TATO |

||

compressor |

BITZER Compressor from France/GEA Blog Compressor from Germany |

||