Advantages and Characteristics:The basic static rated load (Co) of THK linear guide HSR35M1A-HSR35M1LA: The basic static rated load refers to the static load at which the total permanent deformation of the steel ball and the raceway surface at the contact surface subjected to the maximum stress is exactly one ten thousandth of the diameter of the steel ball, in a state where the load direction and magnitude are equal. Due to the increasingly high precision requirements in mechanical processing, the classification of precision levels for important components such as linear guides in machining machinery is becoming finer and finer.

Ball Holder LM Rolling Guide Radial SSR Structure and Features:

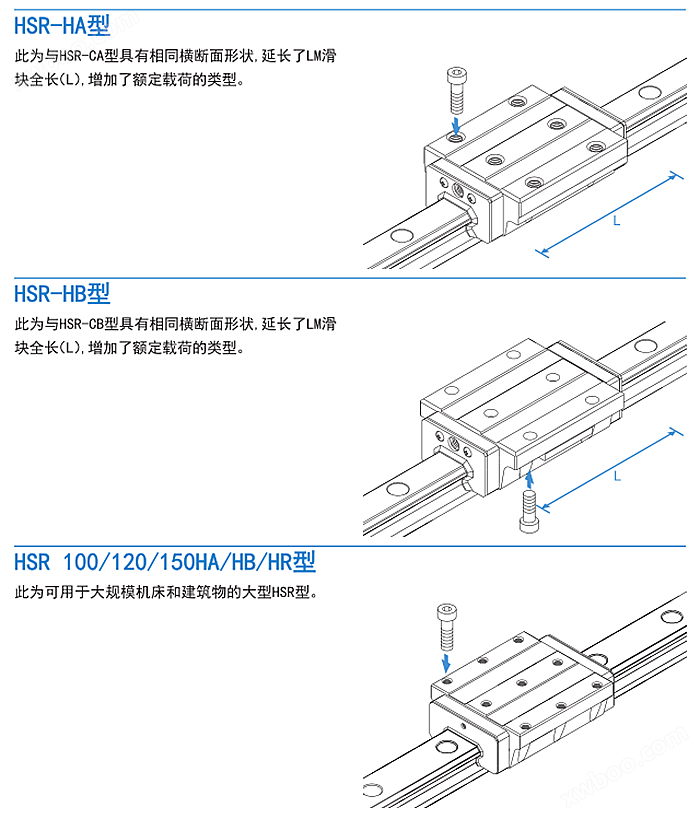

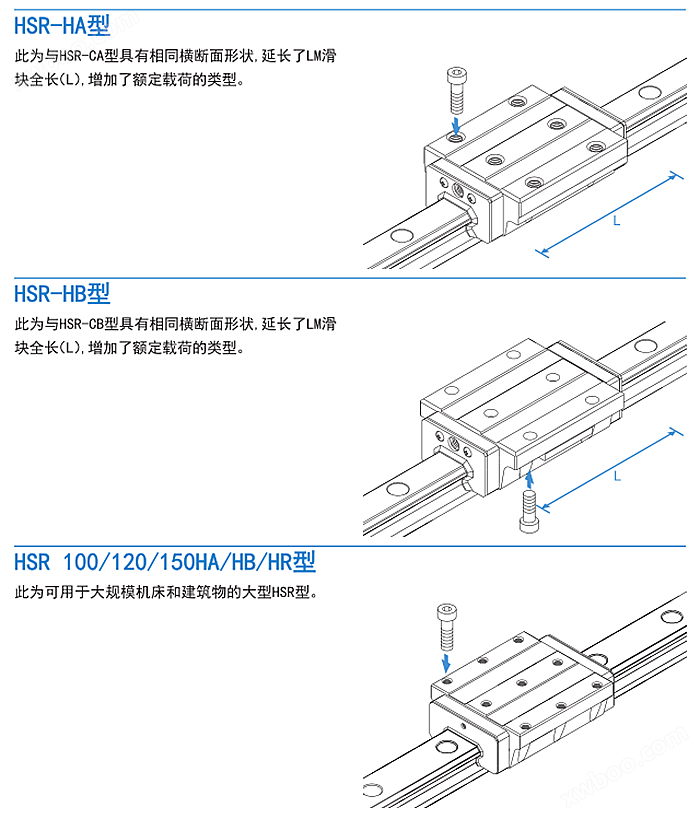

The steel ball rolls along four rows of precision ground rolling surfaces on the LM track and LM slider; By assembling the end cover plate on the LM slider, the steel ball column is cyclically moved.

The LM slider uses a retaining plate to hold the steel ball, so even if the LM slider is removed from the LM track, the steel ball will not fall off (except for HSR8, 10, and 12 types).

In order to ensure that all four directions of action (radial, anti radial, and lateral) on the LM slider have the same rated load, each steel ball column is designed to have a contact angle of 45 degrees? Configuration, so it can be used in any posture. And due to the ability to apply equal preload, it can maintain a low friction coefficient while enhancing rigidity in all four directions. Meanwhile, due to the low cross-sectional height and the high rigidity design of the LM slider, stable high-precision linear motion can be achieved.

Four directional equal load

In order to ensure that all four directions of action (radial, anti radial, and lateral) on the LM slider have the same rated load, each steel ball column is designed to be configured at a contact angle of 45 °, so it can be used in any posture and has a wide range of applications.

High rigidity type

Due to the configuration of steel balls being arranged in four rows with good balance, sufficient preloading can be applied and the rigidity in all four directions can be easily improved.

Automatic heart adjustment ability

Due to THK's unique front combination of circular grooves (DF combination), which has automatic centering capability, it can absorb installation errors even when preloaded, resulting in high-precision, smooth and stable linear motion.

Excellent durability

Even under the action of preloading or bias load, the differential sliding of the steel ball is minimized, achieving long-term maintenance of high wear resistance and accuracy.

Stainless steel type is also available

LM sliders, LM rails, and steel balls can also be made of stainless steel.

The basic static rated load (Co) of THK linear guide HSR35M1A-HSR35M1LA: The basic static rated load refers to the static load at which the total permanent deformation of the steel ball and the raceway surface at the contact surface subjected to the maximum stress is exactly one ten thousandth of the diameter of the steel ball, in a state where the load direction and magnitude are equal. Due to the increasingly high precision requirements in mechanical processing, the classification of precision levels for important components such as linear guides in machining machinery is becoming finer and finer.