Steel rubber composite pipes are made by combining ordinary steel pipes as the skeleton and rubber as the lining layer through special processes. The rubber layer, adhesive formula, and composite process have been fundamentally improved compared to traditional lined rubber pipes at home and abroad. They have the advantages of corrosion resistance, anti-corrosion, scale inhibition, low operating force, low cost, light weight, and wide application fields. They are used in coal power plant ash conveying systems, mine tailings conveying systems, chemical anti-corrosion, coal mine beaches, dredging, pipelines, and other fields.

Product features:

1. The inner wall of the steel rubber composite pipe is as smooth as a mirror, with an absolute roughness of only RA0. 02668, with a running resistance about 17% lower than ordinary steel pipes, can save a lot of power transmission.

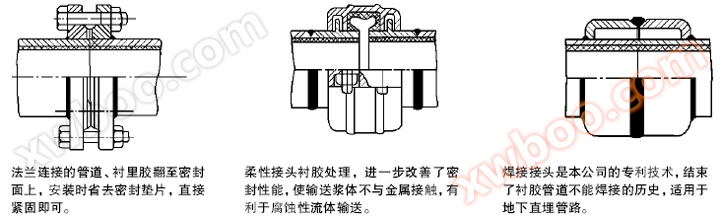

2. Various connection methods

3. Anti corrosion steel rubber composite pipe

According to the different conveying media, the lining rubber of anti-corrosion steel rubber composite pipes can be one or more layers, which can be hard rubber, semi hard rubber or soft rubber. The material can be natural rubber, styrene butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber and EPDM rubber, etc.

Product specifications

Steel rubber composite pipes include special-shaped pipes such as straight pipes, elbows, tees, and variable diameter pipes, with pipe diameter specifications ranging from DN100 to DN1000.

Structural diagram