Component Introduction

POF extruder

Based on Jinming's years of experience in extrusion system design, combined with the processing characteristics of materials and the principles of rheology, a continuous optimization design was developed through simulation to adapt to the processing of various different materials. The extruder was specifically optimized and precision processed for processing polyolefin materials with POF, and has the characteristics of high output, low energy consumption, and good plasticization.

POF mold head

The mold head is designed through simulation, using a streamlined flow channel design with no dead corners, optimizing the resin flow channel and distribution unit, which helps to achieve perfect film thickness tolerances when processing different resins. By adopting a low profile die design, the melt flow performance is optimized, and the self-cleaning performance of the die is excellent, which can effectively shorten the conversion time during formula switching and reduce raw material loss.

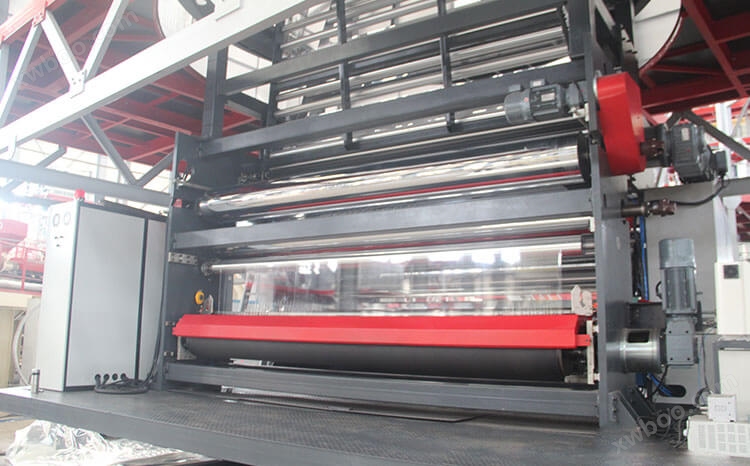

POF winding machine

Equipped with a central rotating winding device, the winding machine is a flip type structure that adopts a center+gap type winding. The winding adopts high-precision taper tension control and has automatic film cutting and roll changing functions.