VIP member

High performance vacuum sealed thermogravimetric analyzer TG 209 F1 Libra

High performance vacuum sealed thermogravimetric analyzer TG 209 F1 Libra

Product details

Faster and more comprehensive characterization of material properties

-NETZSCH has developed a new thermogravimetric analyzer TG 209 F1 Libra based on 50 years of experience in thermogravimetric analysis®This will make thermogravimetric analysis faster, more accurate, and cover a wider temperature range.

BeFlat®Function can double the testing efficiency

-Before measurement, TG 209 F1Libra®Usually, there is no need to spend time making baselines. Unique BeFlat®The function can automatically compensate for any external factors that affect the measurement, reducing working time by up to 50% and leaving more time for measurement.

Rapid heating rate can greatly accelerate testing

- TG 209 F1 Libra®The core of the furnace is made of high-performance ceramics, which not only allows the sample testing temperature to reach 1100 ° C, but also enables a heating rate of up to 200 K/min. Users can obtain the test analysis results of the highest temperature within a few minutes, which is faster than other brands of thermogravimetric analyzers.

Patent c-DTA®Function, can characterize materials more comprehensively and quickly

-NETZSCH has developed a new thermogravimetric analyzer TG 209 F1 Libra based on 50 years of experience in thermogravimetric analysis®This will make thermogravimetric analysis faster, more accurate, and cover a wider temperature range.

BeFlat®Function can double the testing efficiency

-Before measurement, TG 209 F1Libra®Usually, there is no need to spend time making baselines. Unique BeFlat®The function can automatically compensate for any external factors that affect the measurement, reducing working time by up to 50% and leaving more time for measurement.

Rapid heating rate can greatly accelerate testing

- TG 209 F1 Libra®The core of the furnace is made of high-performance ceramics, which not only allows the sample testing temperature to reach 1100 ° C, but also enables a heating rate of up to 200 K/min. Users can obtain the test analysis results of the highest temperature within a few minutes, which is faster than other brands of thermogravimetric analyzers.

Patent c-DTA®Function, can characterize materials more comprehensively and quickly

-Using TG 209 F1 Libra®It can directly measure the temperature of the sample, detect and characterize the exothermic reactions, estimate the melting point of the sample, and obtain more information about the sample behavior without the need for specialized DTA measurements.

Long life high-performance ceramic furnace body

-The newly designed ceramic furnace body, even when used to study materials containing corrosive components, has a lifespan several times longer than traditional thermogravimetric analyzers and can be fully used for analyzing fluorinated or chlorinated polymers. The reaction gas and purge gas flow vertically, which can avoid condensation on the relevant components (sample holder). This is not only beneficial for testing materials, but also reduces the continuous deposition pollution of decomposition products, reducing the cumulative impact of previous tests on subsequent tests.

TG 209 F1 Libra®-Application examples

Decomposition and component analysis of tire rubber

TGA is a standard method for determining the content of rubber components and plasticizers. The thermal decomposition process of a certain rubber composite material is shown in the figure. After the plasticizer (with a content of about 7%) evaporates, the first elastic component in the sample decomposes around 383 ° C (losing 38% weight), and the second elastic component decomposes at 448 ° C (losing 31% weight). The calculated carbon black content is 20% and the ash content is 4%. The peak temperature of DTG indicates that the material is a NR/SBR rubber mixture with added carbon black.

Determination of SEBS+PP plasticizer composition

Component ratio testing of polyamide

Polyamide 66 (PA66) is a thermoplastic polymer widely used in various engineering and technical industries. Usually, appropriate fillers such as glass fibers are added to improve the stiffness of PA66. TGA testing of PA66 can not only determine its decomposition behavior, but also obtain the content of glass fibers. The TGA curve in the following figure clearly shows the ratio of cracked carbon to filled carbon.

Coal Pyrolysis

The pyrolysis of coal is a complex process that involves a large number of chemical reactions. During the heating process, volatile substances (gases and tar) and solid carbon (coke) are mainly generated. Measure coal with a mass of 10mg at a heating rate of 100K/min under a nitrogen atmosphere. The corresponding TGA curve shows several weight loss changes, and the first weight loss of 5.3% (≤ 210 ° C) is likely due to the release of water; After the experiment, the residual amount of the sample was 61.5%.

Fine coal powder TG curve

TG 209 F1 Libra ® - Related attachments

Constant temperature water bath

TG 209 F1 Libra®Equipped with a constant temperature water bath with a refrigeration system, its functions are twofold: firstly, to keep the weighing system in a stable constant temperature working environment, unaffected by heat transfer from the furnace body at high temperatures, and to reduce system drift during long-term testing; secondly, to quickly cool the furnace body, and also to start testing at temperatures lower than room temperature as needed.

Vacuum pump

The instrument can be equipped with different types of vacuum pumps, which can be combined with the automatic vacuum/gas filling system AutoVac to achieve testing under vacuum or pure oxygen free inert atmosphere.

Sample holder

The instrument can be equipped with conventional brackets, highly corrosion-resistant brackets, and high-sensitivity c-DTA®Three different types of sample brackets are available, suitable for different sample situations and testing needs.

Long life high-performance ceramic furnace body

-The newly designed ceramic furnace body, even when used to study materials containing corrosive components, has a lifespan several times longer than traditional thermogravimetric analyzers and can be fully used for analyzing fluorinated or chlorinated polymers. The reaction gas and purge gas flow vertically, which can avoid condensation on the relevant components (sample holder). This is not only beneficial for testing materials, but also reduces the continuous deposition pollution of decomposition products, reducing the cumulative impact of previous tests on subsequent tests.

TG 209 F1 Libra®-Technical parameters

• Temperature range: Room temperature -1100 ° C

• Maximum furnace temperature:> 1100°C

Heating and cooling rates: 0.001 K/min -200 K/min

• Cooling time: 12 minutes (1100 ° C-100 ° C)

• Maximum weighing range: 2000 mg

Resolution: 0.1 µ g

• Sample crucible capacity: standard 85 μ l; Maximum 350 μ l

• Atmosphere: Inert, oxidizing, reducing, static, dynamic

• Built in mass flow meter, precise control of gas flow, including two blow off gases and one protective gas

Vacuum sealed system, with a vacuum degree of up to 10-2mbar (1 Pa)

• Temperature range: Room temperature -1100 ° C

• Maximum furnace temperature:> 1100°C

Heating and cooling rates: 0.001 K/min -200 K/min

• Cooling time: 12 minutes (1100 ° C-100 ° C)

• Maximum weighing range: 2000 mg

Resolution: 0.1 µ g

• Sample crucible capacity: standard 85 μ l; Maximum 350 μ l

• Atmosphere: Inert, oxidizing, reducing, static, dynamic

• Built in mass flow meter, precise control of gas flow, including two blow off gases and one protective gas

Vacuum sealed system, with a vacuum degree of up to 10-2mbar (1 Pa)

TG 209 F1 Libra®-Software functions

TG 209 F1 Libra®The analysis and operation software is based on MS®Windows®Proteus of the system®The software package includes all necessary measurement and data analysis functions. This software package has an extremely user-friendly interface, including easy to understand menu operations and automated workflows, and is suitable for various complex analyses. Proteus software can be installed on the control computer of the instrument for online operation, or installed on other computers for offline use.

TGA analysis features:

TG 209 F1 Libra®The analysis and operation software is based on MS®Windows®Proteus of the system®The software package includes all necessary measurement and data analysis functions. This software package has an extremely user-friendly interface, including easy to understand menu operations and automated workflows, and is suitable for various complex analyses. Proteus software can be installed on the control computer of the instrument for online operation, or installed on other computers for offline use.

TGA analysis features:

Quality change annotation unit:% or mg

Manual or automatic annotation of weightlessness steps

• Quality time/temperature labeling

• Residual quality labeling

• Annotated extrapolation starting and ending points for weightlessness steps

• Can perform first-order differentiation (DTG) and second-order differentiation on thermogravimetric curves, and can annotate peak temperatures

Automatically perform baseline deduction and buoyancy correction

• c-DTA®: Can annotate thermal effect characteristic temperature and peak area (optional)

• Super-Res®(Super resolution function): Automatic rate control for weight loss, automatic separation of adjacent steps (optional)

Modulation TGA function (optional)

The software complies with GLP and GMP standards

Manual or automatic annotation of weightlessness steps

• Quality time/temperature labeling

• Residual quality labeling

• Annotated extrapolation starting and ending points for weightlessness steps

• Can perform first-order differentiation (DTG) and second-order differentiation on thermogravimetric curves, and can annotate peak temperatures

Automatically perform baseline deduction and buoyancy correction

• c-DTA®: Can annotate thermal effect characteristic temperature and peak area (optional)

• Super-Res®(Super resolution function): Automatic rate control for weight loss, automatic separation of adjacent steps (optional)

Modulation TGA function (optional)

The software complies with GLP and GMP standards

TG 209 F1 Libra®-Application examples

Decomposition and component analysis of tire rubber

TGA is a standard method for determining the content of rubber components and plasticizers. The thermal decomposition process of a certain rubber composite material is shown in the figure. After the plasticizer (with a content of about 7%) evaporates, the first elastic component in the sample decomposes around 383 ° C (losing 38% weight), and the second elastic component decomposes at 448 ° C (losing 31% weight). The calculated carbon black content is 20% and the ash content is 4%. The peak temperature of DTG indicates that the material is a NR/SBR rubber mixture with added carbon black.

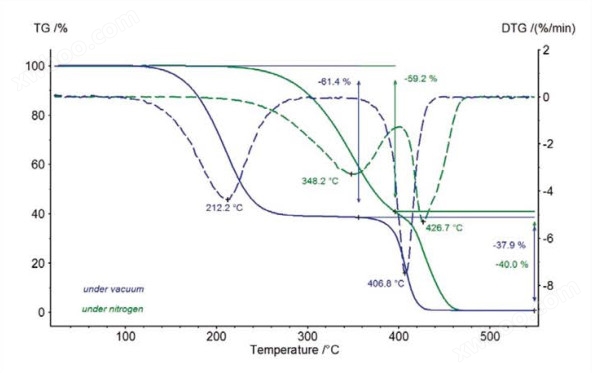

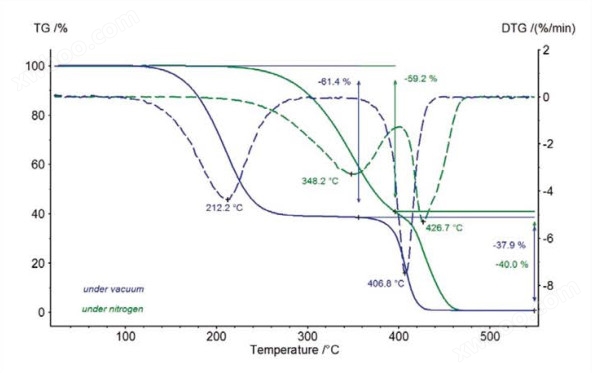

Determination of SEBS+PP plasticizer composition

Thermoplastic elastomers are a type of copolymer or blend that combines thermoplastic and elastic properties, and are very easy to process, such as injection molding. Under conventional dynamic blowing atmosphere conditions, the decomposition steps of small molecule plasticizers and the decomposition steps of elastic components overlap and cannot be separated in this type of material. When tested under vacuum, the boiling point of plasticizers decreases and volatilization occurs earlier, making the quantitative determination of their content more accurate.

TG 209 F1 Libra ™ Can be equipped with a unique fully automatic vacuum system. As shown by the blue curve in the figure, the separation of the two weight loss processes is more pronounced due to the decrease in the vapor pressure of the plasticizer during vacuum testing.

TG 209 F1 Libra ™ Can be equipped with a unique fully automatic vacuum system. As shown by the blue curve in the figure, the separation of the two weight loss processes is more pronounced due to the decrease in the vapor pressure of the plasticizer during vacuum testing.

Component ratio testing of polyamide

Polyamide 66 (PA66) is a thermoplastic polymer widely used in various engineering and technical industries. Usually, appropriate fillers such as glass fibers are added to improve the stiffness of PA66. TGA testing of PA66 can not only determine its decomposition behavior, but also obtain the content of glass fibers. The TGA curve in the following figure clearly shows the ratio of cracked carbon to filled carbon.

Coal Pyrolysis

The pyrolysis of coal is a complex process that involves a large number of chemical reactions. During the heating process, volatile substances (gases and tar) and solid carbon (coke) are mainly generated. Measure coal with a mass of 10mg at a heating rate of 100K/min under a nitrogen atmosphere. The corresponding TGA curve shows several weight loss changes, and the first weight loss of 5.3% (≤ 210 ° C) is likely due to the release of water; After the experiment, the residual amount of the sample was 61.5%.

Fine coal powder TG curve

Magnesium stearate

Commercially available magnesium stearate is generally made by mixing several fatty acid salts in different proportions and is widely used as a drug excipient. TGA testing shows that magnesium stearate undergoes three weight loss steps within the temperature range of 200 ° C: 0.5%, 1.1%, and 2.1%. If analyzed using a TGA/FTIR analyzer, it can be preliminarily determined from the corresponding spectra that all three weight losses are due to the evaporation of water.

Commercially available magnesium stearate is generally made by mixing several fatty acid salts in different proportions and is widely used as a drug excipient. TGA testing shows that magnesium stearate undergoes three weight loss steps within the temperature range of 200 ° C: 0.5%, 1.1%, and 2.1%. If analyzed using a TGA/FTIR analyzer, it can be preliminarily determined from the corresponding spectra that all three weight losses are due to the evaporation of water.

Magnesium stearate TG curve, sample mass: 5.8mg, heating rate: 10K/min, atmosphere: N2

mica

TGA test analysis shows the weight loss process of mica dehydration and dehydroxylation at lower temperatures. TG 209 F1 Libra ™ Equipped with a new type of ceramic furnace body, it has a wide temperature testing range, with a maximum temperature of 1100 ℃, and can observe the characteristic weight loss temperature of mica at 1093 ° C.

TGA test analysis shows the weight loss process of mica dehydration and dehydroxylation at lower temperatures. TG 209 F1 Libra ™ Equipped with a new type of ceramic furnace body, it has a wide temperature testing range, with a maximum temperature of 1100 ℃, and can observe the characteristic weight loss temperature of mica at 1093 ° C.

Mica TG curve

Thermal decomposition of dolomite under CO2 atmosphere

Dolomite (CaMg (CO3) 2) was tested under a nitrogen atmosphere, and the weight loss steps of its thermal decomposition overlapped with each other; When tested in a CO2 atmosphere, these decomposition steps will be clearly separated. The c-DTA curve provides further information: both steps of decomposition are endothermic.

Dolomite (CaMg (CO3) 2) was tested under a nitrogen atmosphere, and the weight loss steps of its thermal decomposition overlapped with each other; When tested in a CO2 atmosphere, these decomposition steps will be clearly separated. The c-DTA curve provides further information: both steps of decomposition are endothermic.

TG 209 F1 Libra ® - Related attachments

Constant temperature water bath

TG 209 F1 Libra®Equipped with a constant temperature water bath with a refrigeration system, its functions are twofold: firstly, to keep the weighing system in a stable constant temperature working environment, unaffected by heat transfer from the furnace body at high temperatures, and to reduce system drift during long-term testing; secondly, to quickly cool the furnace body, and also to start testing at temperatures lower than room temperature as needed.

Vacuum pump

The instrument can be equipped with different types of vacuum pumps, which can be combined with the automatic vacuum/gas filling system AutoVac to achieve testing under vacuum or pure oxygen free inert atmosphere.

Sample holder

The instrument can be equipped with conventional brackets, highly corrosion-resistant brackets, and high-sensitivity c-DTA®Three different types of sample brackets are available, suitable for different sample situations and testing needs.

crucible

The instrument provides a variety of crucibles with different textures and sizes to meet the needs of experiments, including alumina crucibles, platinum rhodium crucibles, aluminum crucibles, graphite and quartz crucibles, etc.

Calibration standard sample

The instrument provides a temperature calibration standard series, covering the testing temperature range of 10 ° C to 1100 ° C. These standard calibration materials are suitable for testing in accordance with ASTM and CEI-IEC standards.

Automatic Sample Injection System ASC

TG 209 F1 Libra®Can be equipped with an automatic sampling system ASC, which can automatically and effectively perform routine testing to meet the needs of quality control and research and development. Testing does not require the presence of experimenters and can be conducted day and night, even on weekends, allowing the instrument to be fully utilized.

The newly designed ASC can handle 192 crucibles evenly distributed on two replaceable sample boxes. Multiple types of crucibles can be used, with a maximum diameter of 8mm and a maximum height of 8mm. ASC's four needle gripper can handle different crucibles. For the purpose of calibration and correction testing, ASC provided an additional 12 crucible position fixed injection strips. The crucible in motion can be identified. All crucible and crucible cover information on ASC are stored in the database. There is an automatically controlled transparent box cover above the sample box. After closing the lid, the space above the sample box is purged by the branched gas integrated in the lid. The blowing air is a specialized branch for ASC, designed for opening and closing lids, and its flow rate has been optimized through regulation. The built-in 'remove crucible cover' function can be executed while the sample is waiting to be inserted into the DSC unit. An optional piercing device can also be equipped to pierce the crucible cover before measurement. The DSC system has a recycling bin for discarding crucible covers and non reusable crucibles. Sample boxes can also be used for sample archiving. In order to better identify different samples, each sample box has a unique serial number, and each sample grade on it has a two-dimensional number (such as A5, B2...). The crucible/crucible cover database has tray recognition function. This ASC system can also be used for the new DSC 204 F1 Phoenix®Differential scanning calorimeter.

Each sample on the injector can be individually set with different experimental conditions and analytical labeling methods, NETZSCH Proteus®The software's easy to understand setup wizard will guide operators to easily complete a series of measurement programs. Moreover, tests that have not been scheduled in advance can also be inserted into pre-set programs, which is very flexible.

For unstable or volatile samples, ASC also provides an automatic perforation device that can be set to puncture the sealed crucible before the measurement begins.

The instrument provides a variety of crucibles with different textures and sizes to meet the needs of experiments, including alumina crucibles, platinum rhodium crucibles, aluminum crucibles, graphite and quartz crucibles, etc.

Calibration standard sample

The instrument provides a temperature calibration standard series, covering the testing temperature range of 10 ° C to 1100 ° C. These standard calibration materials are suitable for testing in accordance with ASTM and CEI-IEC standards.

Automatic Sample Injection System ASC

TG 209 F1 Libra®Can be equipped with an automatic sampling system ASC, which can automatically and effectively perform routine testing to meet the needs of quality control and research and development. Testing does not require the presence of experimenters and can be conducted day and night, even on weekends, allowing the instrument to be fully utilized.

The newly designed ASC can handle 192 crucibles evenly distributed on two replaceable sample boxes. Multiple types of crucibles can be used, with a maximum diameter of 8mm and a maximum height of 8mm. ASC's four needle gripper can handle different crucibles. For the purpose of calibration and correction testing, ASC provided an additional 12 crucible position fixed injection strips. The crucible in motion can be identified. All crucible and crucible cover information on ASC are stored in the database. There is an automatically controlled transparent box cover above the sample box. After closing the lid, the space above the sample box is purged by the branched gas integrated in the lid. The blowing air is a specialized branch for ASC, designed for opening and closing lids, and its flow rate has been optimized through regulation. The built-in 'remove crucible cover' function can be executed while the sample is waiting to be inserted into the DSC unit. An optional piercing device can also be equipped to pierce the crucible cover before measurement. The DSC system has a recycling bin for discarding crucible covers and non reusable crucibles. Sample boxes can also be used for sample archiving. In order to better identify different samples, each sample box has a unique serial number, and each sample grade on it has a two-dimensional number (such as A5, B2...). The crucible/crucible cover database has tray recognition function. This ASC system can also be used for the new DSC 204 F1 Phoenix®Differential scanning calorimeter.

Each sample on the injector can be individually set with different experimental conditions and analytical labeling methods, NETZSCH Proteus®The software's easy to understand setup wizard will guide operators to easily complete a series of measurement programs. Moreover, tests that have not been scheduled in advance can also be inserted into pre-set programs, which is very flexible.

For unstable or volatile samples, ASC also provides an automatic perforation device that can be set to puncture the sealed crucible before the measurement begins.

Online inquiry