FT8511 series coupled magnetostrictive liquid level gauge

The FT8511 series coupled magnetostrictive liquid level gauge is based on the principle of magnetostriction. The instrument consists of a magnetostrictive level gauge and a magnetic flap level gauge, with a two-wire intrinsic safety design. It is mainly used for accurate and reliable process level measurement and tank capacity measurement and control in measurement and control fields such as petroleum, power, chemical, metallurgical, and light industry.

This product consists of a magnetic replica level gauge and a magnetostrictive level gauge bundled together.

measuring principle

The magnetostrictive sensor is the core of the magnetostrictive liquid level monitoring system, and the core sensitive element of the sensor (magnetostrictive wire) has the characteristics of high strain value and strong electrical (magnetic) mechanical wave conversion ability, which can convert small magnetic vector changes into mechanical waves. The sensor consists of a stainless steel rod and a built-in magnetostrictive wire. When the electric pulse generated by the pulse generator in the electronic component is transmitted along the magnetostrictive wire inside the steel pipe, the electric pulse current simultaneously generates a circular magnetic field perpendicular to the magnetostrictive wire and propagates along the magnetostrictive wire at the speed of light; When the electric pulse annular magnetic field meets the inherent magnetic field of the float inside the magnetic flap measuring cylinder, the magnetic fields of the two interact, generating instantaneous torque and forming a mechanical torque wave pulse on the magnetostrictive line. The mechanical torque wave is transmitted back to the electronic component at a certain speed. Electronic components pick up pulses, and by measuring the time difference between the emitted electrical pulse and the returned torque wave pulse, the height or level of the measured liquid surface can be accurately calculated.

characteristic

High temperature and high pressure applications: -196~450 ℃ (-321~842 ℉), 10Mpa (1450psi)

Dual display output: The instrument can output 4-20mA signal for remote transmission to the main control room while displaying on the magnetic flip panel

Easy installation: Adopting an external installation method, installation, debugging, and maintenance can be carried out without affecting production

High precision: The instrument accuracy can reach 1mm

Modular design: Instrument sensors and electronic units can be interchangeable and universal, facilitating spare parts and maintenance

Split installation: The unit and probe can be installed separately, suitable for more harsh and dangerous sites, and easy to debug and maintain

HART communication: Comes with industrial field two-wire 4-20mA HART communication

On site button calibration: It can directly calibrate high and low liquid levels through the two buttons at the top of the unit, which is convenient and fast to use

Typical applications

Finished oil storage tank

Liquefied gas storage tank

Various chemical reagents

Process tank leakage detection

Water and sewage treatment

Other high-precision liquid level detection

performance index

Measurement equipment level: CAT I level, transient rated voltage 1500V, cannot be used for levels other than CAT I level

Output: 1 4-20mA 2 4-20mA, HART 3 RS485/Modbus 4 single 4-20mA, dual level HART

Measurement method: can be set as level/distance measurement method by software

Display: on-site magnetic flip panel display, on-site LCD display (optional)

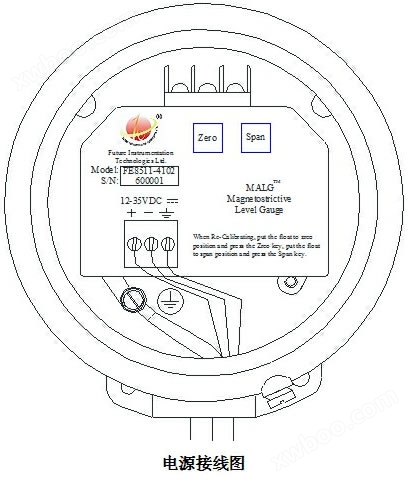

Power supply: 12-35VDC; Requirement for intelligent communication: power supply of 15-35VDC

Power: less than 0.5W

Accuracy: ≤ 0.1% FS or 1mm (whichever is greater)

Resolution: ≤ 0.04% FS or 0.4mm (whichever is greater)

Repeatability: ≤ 0.04% FS or 0.4mm (whichever is greater)

Linear correction: Software selectable 10 point nonlinear correction (if necessary)

Temperature effect: 0.05/10 ℃ (18 ℉)

Load resistance: Output circuit load resistance capacity of 600 Ω at 24VDC

Environmental temperature: T5: -40 to+70 ℃ (-40 to 158 ℉); T6: -40 to+60 ℃ (-40 to 140 ℉) (The influence of medium temperature on ambient temperature cannot exceed the instrument's requirements for ambient temperature)

Response time: 2 seconds

Delay: Adjustable from 1 to 90 seconds (software adjustable)

Range: 0-5m (hard pole), 0-20m (soft cable)

Dead zone: Upper dead zone ≤ 1/2 of the float height,

Dead zone pole type: one floating ball height; Cable type: 250mm~450mm

Maximum process temperature: -196 to+450 ℃ (-321 to 778 ℉) (see probe performance indicators for details)

Maximum process pressure: 10MPa (1450psi) (see probe performance indicators for details)

Medium density: 0.38g/cm3 to 2g/cm3

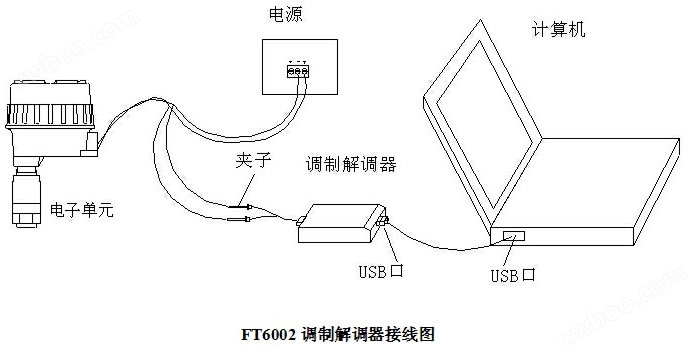

Split cable length: The longest split cable is 3 meters

Electrical interface: M20X1.5 (optional 3/4 "NPT)

Process connection: NPT thread installation (standard, optional BSPT), flange installation (optional)

Explosion proof rating: ExiaIIBT5/T6 Ga and Exd IIBT5/T6 Gb

Protection level: Compliant with IP67 protection standard

Certification: CMC, PCEC/NEMSI. For other certifications, please consult the manufacturer

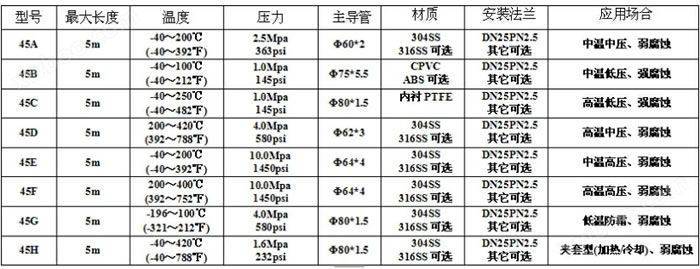

Probe indicators

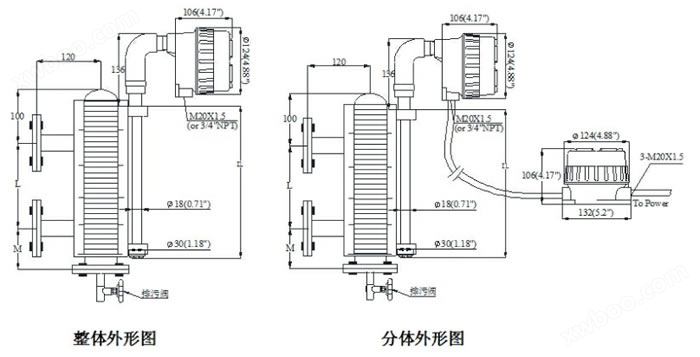

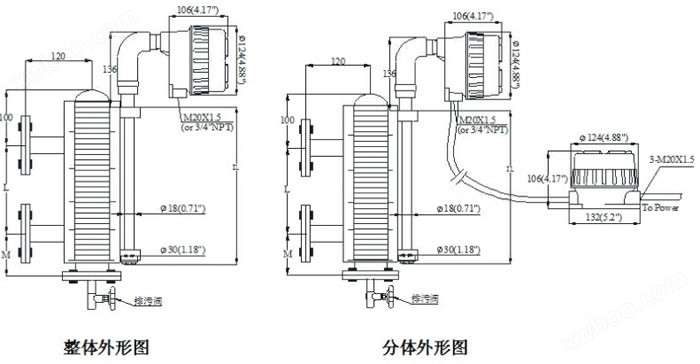

Outline drawing of magnetic coupling level gauge

Outline drawing of magnetic coupling level gauge

Note: L quantity and (flange center distance)

M varies in length according to the density of the medium, with a minimum of 180mm

The installation distance between the magnetostrictive probe and the main tube is 3-30mm (standard 10mm)

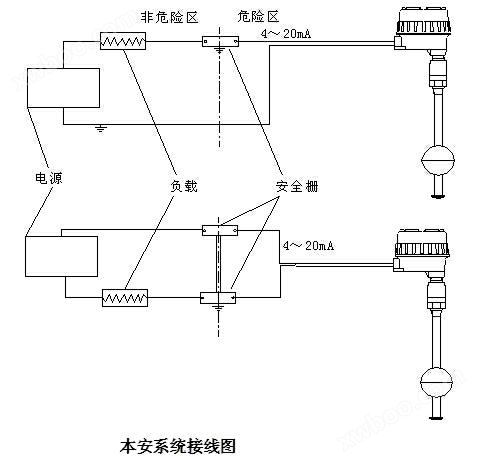

Wiring diagram of magnetic coupling level gauge

The FT8511 series magnetic coupling level gauge is an intrinsic safety instrument. When installed in hazardous environments, a certified safety barrier needs to be added to its power supply circuit. Both single and double barriers can be used, but the connection method is different. Figure 4.5 shows the system wiring diagram, with examples of single and double barrier installations. Please consult our company or our agent for certified safety barrier products. Please refer to the instructions for the use of safety barriers for grounding requirements. The maximum impedance of cables, loads, and safety barriers under 24VDC power supply is 600 Ω. The level gauge is powered by a certified safety barrier, and the requirements for the safety barrier of this level gauge are:

Uo=28VDC

Io=93mA

Po=0.65W

Co=0.6uF

Lo=15mH

The safety parameters of the instrument are as follows:

Ui=30V

Ii=99.01mA

Pi=0.74W

Ci=2nF

Li=50uH

The wiring of the explosion-proof on-site system does not require safety barriers, but all cables are required to be in explosion-proof tubes.

In the instrument current loop, it should be ensured that the load on the instrument power supply side is greater than 250 ohms. If necessary, a 250 ohm resistor should be directly added to the power supply side to facilitate smooth communication.

Installation requirements for magnetic coupling level gauge

The installation, use, and maintenance of the product should comply with the product installation, commissioning, and use instructions, as well as GB50257 "Electrical Equipment Installation Engineering"

Code for Construction and Acceptance of Electrical Installations in Explosive and Fire Hazardous Environments ", GB3836.15" Electrical Equipment for Explosive Gas Environments "

Part 15: Electrical Installation in Hazardous Areas (excluding Coal Mines) "and GB3836.13" Electrical Equipment for Explosive Gas Environments Part 13

According to the relevant provisions of "Maintenance of Electrical Equipment for Explosive Gas Environments".

When installing instruments, they should be kept as far away as possible from vibration sources, high temperature environments, corrosive air, and any places that may cause mechanical damage. in compliance with

If the requirements cannot be met, please replace the instrument with a different component and shape. The ambient temperature should be between -40 and 70 ℃ (-40 and 158 ℉).

The instrument installation area requires lightning protection devices to prevent lightning strikes.

It is prohibited to use single component ambient temperature sulfurized sealant inside the instrument casing. This substance often contains acetic acid, which will corrode electronic components. answer

Using a special two-component sealant (non corrosive).

The instrument casing is equipped with grounding terminals, and users should ensure reliable grounding during installation and use. When used for non-metallic cans, standard ground should be provided on site,

Cannot be connected to the power ground.

The electrical interface needs to be equipped with cable sealing joints with a protection level of IP65 that meet the requirements of GB4208 standard to ensure reliable sealing and prevent damage

Damage to the electronic unit of the instrument caused by water ingress or other corrosive gases.

Do not disassemble the sensor or loosen the sealing nut to avoid probe leakage.

The installation of threads or flanges should be firmly connected to the container, reliably sealed, and have good electrical contact. Except for the connection, the other parts of the sensor are not

It should be in contact with the container to ensure the normal movement of the float.

During the installation of the probe, there should be no ferromagnetic materials within a range of 200mm from the probe.

Instruments installed according to explosion-proof standards must be equipped with explosion-proof type fillers certified by GB3836.1 and GB3836.2 explosion-proof standards for electrical interfaces

Material letter or explosion-proof steel pipe sealing joint.

The instrument circuit installed according to intrinsic safety standards must be equipped with safety barriers certified by GB3836.1 and GB3836.4 explosion-proof standards.

The ripple of 24VDC power supply shall not exceed 100mV.

The instrument connection cable shall comply with the requirements of IEC60245/60227 standard. Recommend using armored shielded 3-core cables with an outer diameter not exceeding

12mm, cable conductor material is copper, conductor cross-sectional area is 0.13-2.1mm2 (AWG14-26), cable insulation strength is 1500V, not

Long distance unshielded parallel connection with AC power cables.

When using and maintaining on site, the principle of "no opening with power on" must be followed, and it is recommended to shut off the power for 10 minutes before operation.