The FT8020 series is an intelligent point switch used for limit control of storage and transportation of raw materials, products, and other materials in both civilian and industrial processes. It is suitable for most situations involving solid particles, powders, slurries, liquids, and liquid-liquid interfaces.

The instrument uses characteristic software based on our company's unique hardware technology to ensure effective identification and judgment of the object level.

The power supply of this instrument adopts a universal design with AC and DC power supplies at the same end. In principle, industrial standard AC and DC power supplies such as 220VAC, 110VAC, and 24VDC can be directly connected to the two terminal holes on the leftmost side of the top of the electronic unit without polarity requirements.

measuring principle

Radio frequency admittance level control technology is a level control technology developed from capacitive level control technology, which has better anti hanging material (the material adhered to the sensor is called hanging material) performance, more reliable operation, more accurate measurement, and wider applicability. The meaning of "conduction" in "radio frequency admittance" is the reciprocal of impedance in electricity, which is composed of resistive, capacitive, and inductive components. "Radio frequency" refers to high frequency, so radio frequency admittance technology can be understood as a method of measuring admittance using high-frequency current.

The important difference between point RF admittance technology and capacitance technology is the use of three terminal shielding technology and the diversity of measurement parameters. Not only does it solve the problem of parasitic capacitance temperature drift in connecting cables, but it also solves the problem of sensor hanging material impact.

characteristic

No debugging required: No on-site debugging of the instrument is needed

Universal power supply: 21-35VDC and 30-265VAC universal

Maintenance free: Unlike anti rotation, vibration bar or other mechanical switches, its components will not cause blockage, breakage, damage or wear, and do not require regular maintenance, cleaning or replacement

Anti hanging material: Three end shielding technology allows it to ignore the impact of hanging walls or sensing components, without the need for regular cleaning or repeated debugging

Widely applicable: Process temperature ranges from -183 ℃ to+815 ℃, pressure ranges from vacuum to 100bar

Three color indicator lights: red light - alarm, green light - normal, yellow light - system fault, real-time reflection of instrument status

Convenient electrical connection: Dual electrical interface design makes the wiring process safer and more convenient

Strong driving capability: 500 Ω between the center end and the shielding end, and 150 Ω between the shielding end and the ground

Spark protection: Built in 1000V spark protection, surge suppression, and anti-static 4kV/8kV to protect circuit units from damage and ensure normal operation

Electronic unit: Hockey pock design for easy installation and reliable operation

Easy installation: The instrument can be installed through the threaded port or flange on the tank, and can be installed as a whole or in separate parts, which is simple, convenient, easy to debug, and fast

Typical applications

Liquid: Conductive liquid or insulating liquid (including liquefied gas)

Slurry: conductive slurry and insulating slurry

Particles: grains, plastic sheets, coal, etc

Interface: Two liquid interfaces with different dielectric constants

Powder: plastic powder, cement, fly ash, etc

performance index

Measurement equipment level: CAT II, transient rated voltage 2500V, cannot be used for levels other than CAT I and CAT II

Output: DPDT relay (double pole double throw) and alarm light output

Contact capacity: 250VAC: 1A inductive, 3A non inductive

Power supply: Universal power supply, 30-265VAC, 50/60Hz and 21-35VDC automatic adaptation

Dissipative power: 2W

Resolution: 0.2pF or less

Setpoint accuracy:<1mm (0.04 ″) or 0.5pF (conductive material); <20mm (0.79 ") or 0.5pF (insulation material)

Load resistance: 500 Ω between center end and shield end, 150 Ω between shield end and ground

Alarm mode: can be set on-site as high-level alarm and its fault insurance mode or low-level alarm and its fault insurance mode

Alarm light output: red light - level alarm; Green light - level normal; Yellow light - Fault alarm

Debugging: For the vast majority of on-site implementations, there is no need for debugging or manual settings can be changed on-site

Re debugging: It can be set to a reset state on site, and will automatically calibrate and debug the next power on

On site material types can be set: divided into conductive materials and insulating materials

On site adjustable range: 130pF, 30pF two levels

Environmental temperature: T5: -40 to+70 ℃ (-40 to 158 ℉); T6: -40 to+60 ℃ (-40 to 140 ℉) (The influence of medium temperature on ambient temperature cannot exceed the instrument's requirements for ambient temperature)

Response time:<1 second

Delay: 1-70 seconds, divided into 16 levels

Power on self-test time: about 5 seconds (during normal operation)

Safety barrier: built-in current limiting and quadruple voltage limiting protection safety barrier

Electrostatic spark protection (for sensors): anti surge impact 1KV, anti-static 4KV/8KV

RF protection (built-in filter): The whole machine is tested by injecting current through a 10V/m electromagnetic field and a 3V/m electromagnetic field in space

Probe length: 0.5m (19.7 ") (standard), 0.1m (3.9") to 20m (787.4 ") (optional)

Cable length: 5m (19.7 ") (standard), 0.1 (3.9") to 50m (1968.5 ") (optional),> 50m (1968.5 ") to 100m (3937") (consult manufacturer)

Electrical interface: Dual M20 × 1.5 (optional 3/4 "NPT)

Process connection: BSPT thread installation (standard, optional NPT), flange installation (optional)

Shell material: die cast aluminum with epoxy coating

Shell protection: Compliant with IP67 protection standard

Explosion proof grade: Exd ia [ia Ga]IIC T5/T6 Gb

Certification: PCEC/NEMSI. For other certifications, please consult the manufacturer

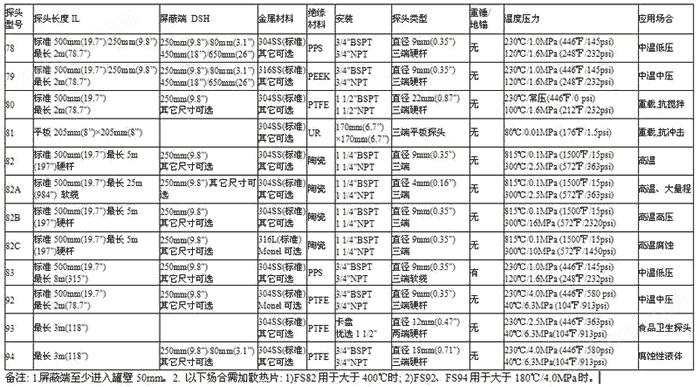

2.2 Probe performance indicators

Installation requirements for FT8020

The installation, use, and maintenance of the product should comply with the relevant provisions of the product installation, commissioning, and use instructions, GB50257 "Code for Construction and Acceptance of Electrical Equipment in Explosive and Fire Hazardous Environments", GB3836.15 "Electrical Equipment for Explosive Gas Environments Part 15: Electrical Installation in Hazardous Areas (excluding Coal Mines)", and GB3836.13 "Electrical Equipment for Explosive Gas Environments Part 13: Maintenance of Electrical Equipment for Explosive Gas Environments".

When installing instruments, they should be kept as far away as possible from vibration sources, high temperature environments, corrosive air, and any places that may cause mechanical damage. If the requirements cannot be met, please replace the instrument with a new component. The ambient temperature should be between -40 and 70 ℃ (-40 and 158 ℉).

The instrument installation area requires lightning protection devices to prevent lightning strikes.

It is prohibited to use single component ambient temperature sulfurized sealant inside the instrument casing. This substance often contains acetic acid, which will corrode electronic components. Special two-component sealant (non corrosive) should be used.

The instrument casing is equipped with grounding terminals, and users should ensure reliable grounding during installation and use. When used for non-metallic cans, a standard ground should be provided on site and cannot be connected to the power ground.

The electrical interface should be equipped with cable sealing joints with a protection level of IP65 that meet the requirements of GB4208 standard to ensure reliable sealing and prevent damage to the instrument electronic unit caused by water ingress or other corrosive gases.

Do not disassemble the sensor or loosen the sealing nut to avoid probe leakage.

The installation of sensors should avoid material flow or inlet/outlet ports. If there are no other installation locations, protective covers or partitions should be added.

The installation of threads or flanges should be firmly connected to the container, reliably sealed, and have good electrical contact. Except for the connection, other parts of the sensor should not come into contact with the container to ensure good insulation.

When installing the sensor horizontally, it should be slightly tilted downwards at an angle of 10-20 °.

When installing hard rod sensors, the installation space should be considered, with a distance of at least 100mm from the tank wall. Cable sensors should be straightened after installation, with a distance of at least 300mm from the tank wall to avoid short circuits to the ground.

In situations where there is significant mixing, airflow, and material flow fluctuations inside the container to be tested, in addition to avoiding direct mechanical damage to the sensor, indirect mechanical damage such as long-term fatigue of the sensor material should also be considered. Therefore, it is recommended to install protective measures such as intermediate support and bottom anchor fixation for the sensor. Please note that the support and ground anchor should be insulated from the sensor, and the insulation material should be selected from materials with high insulation strength, low hardness, lubrication function, and no wear on the sensor (such as PTFE). If not, please consider replacing the sensor regularly to avoid sensor damage and chain loss.

When measuring large quantities of solid particles, the heavy hammer at the end of the sensor should be as high as possible above the cone angle of the silo. If it is necessary to enter the conical section, the maximum entry size should not exceed 20% of the diameter of the silo.

The non active section of the sensor should enter the tank at least 50mm. When the cable sensor is installed horizontally, the hard rod part entering the tank should not be less than 200mm, and when installed vertically, the hard rod part entering the tank should not be less than 100mm.

Instruments installed according to explosion-proof standards must be equipped with explosion-proof stuffing boxes or explosion-proof steel pipe sealing joints certified by GB3836.1 and GB3836.2 explosion-proof standards for electrical interfaces.

The ripple of 24VDC power supply shall not exceed 100mV.

The instrument connection cable shall comply with the requirements of IEC60245/60227 standard. It is recommended to use armored shielded 3-core cables with an outer diameter of no more than 12mm. The cable conductor material is copper, and the cross-sectional area of the conductor is 0.13-2.1mm2 (AWG14-26). The insulation strength of the cable is 1500V. Long distance unshielded cables cannot be used in parallel with AC power cables.

When using and maintaining on site, the principle of "no opening with power on" must be followed, and it is recommended to shut off the power for 10 minutes before operation.