1、 Double column universal material testing machine

Double column universal material testing machine, also known as universal tensile machine, tensile testing machine or electronic tensile machine, is mainly used for:

Tensile, peel, tear, compression, bending, stacking cyclic fatigue testing

2、 Compliant with technical standards

GB, ISO, DIN, ASTM, JIS and other international standards for testing and providing data

3、 Main technical indicators:

Maximum external dimensions: 520 * 450 * 1600

Equipment weight: 225kg

Force units: freely switch between kgf, N, Lbf, KN, tf (SI), tf (long), tf (short), ozf, etc

Maximum experimental space: 700mm effective space above and below, 600mm left and right.

Maximum travel: 1600mm Other specifications can specify 1350mm, 1400mm, 1500mm travel, etc

Maximum testing force: 2000kg

Power display resolution: 1/500000

Accuracy of force testing: 0.5

Displacement display resolution: 0.0001mm

Speed control range: 0.001-510mm/min

Speed accuracy: 0.001

Beam movement: Jogging function for moving the upper and lower beams

4、 Measurement software functions:

Test item: Determine the mechanical properties and relevant physical parameters of various materials under tension, compression, bending, shear, tearing, peeling, puncture and other states. It can be used for stretching, compression, three-point bending, four point bending, shearing, tearing, peeling, finished shoe puncture, cardboard box holding pressure, foam cyclic compression, spring tension compression, and various dynamic and static cyclic tests.

Data management: Store in WINDOWS standard document format, freely set storage path and file name.

Report formats: Word, Excel, PDF, etc

Communication function: R232、USB

One click switching between multiple languages: Simplified, Traditional, and English. The Ten Language Edition will soon be available in Japanese, Korean, Russian, German, French, Spanish, Portuguese, and other languages.

Other instructions: PC Windows operation

5、 Structure and materials:

Base: Combination sheet metal structure, easy to maintain

Guide pillar: made of high-strength special steel

Column cover: Made of high-quality aerospace specific aluminum alloy casting (treated with special dual color mixed spraying technology)

Beam: Made of high-strength special steel, it will never deform.

6、 Main accessories:

Power: Full digital AC closed-loop servo system (driver and motor)

Reduction device: Adopting foreign technology synchronous gear multi-stage transmission structure, it has the characteristics of no noise and high efficiency.

Screw: High precision gapless ball screw

Force sensor: comply with standard GB/T7551-2008, insulation resistance ≥ 5000 megaohms, sensitivity: 1.9987mV/V

Displacement sensor: Panasonic incremental type

Main electrical components: famous brands such as Omron, Shilin, Mitsubishi, etc

7、 Safety protection devices and usage conditions

Upper limit: Non mechanical contact photoelectric sensing device

Lower limit: Non mechanical contact photoelectric sensing device

Motor overload: phase loss, undervoltage, overvoltage, overcurrent, overheating, position deviation, regenerative overload, overload, etc

Electrical short circuit: overvoltage, overcurrent, and short circuit protection devices.

Installation site: environmentally friendly and pollution-free environment, laboratory.

Environmental temperature: The laboratory temperature is between 23-25 degrees Celsius

Environmental humidity: 80%

Power supply voltage: single-phase AC220V

Power capacity: 500W

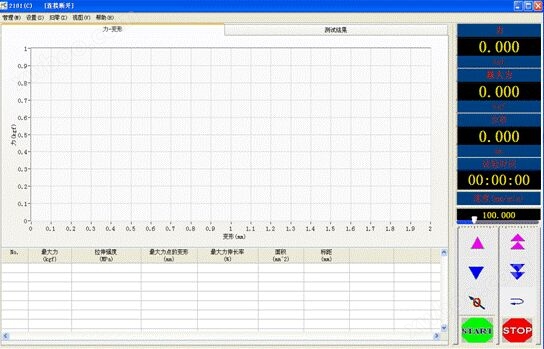

8、 Software operation screen

9、 Recommended JTAEN instruments and equipment

Image measuring instrument, fully automatic dispensing machine, tensile testing machine, three coordinate measuring instrument