Component Introduction

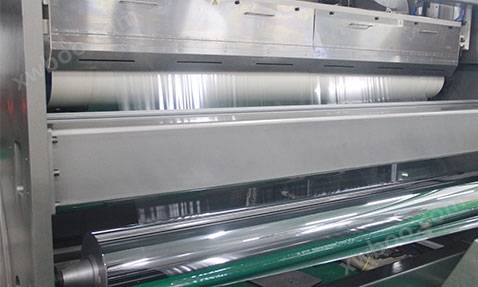

Horizontal MDO longitudinal pulling unit

The MDO longitudinal pulling unit mainly consists of preheating roller, shaping roller, stretching roller, threading system, pressure roller, tension roller, main transmission system, infrared heater, wall panel, base, and water and water circulation heating system. The thick sheet is heated to a certain temperature on the preheating roller and sent to the stretching roller. Due to the different circumferential speeds of the two stretching rollers, the thick sheet is stretched. The stretched film is shaped on the shaping roller and then sent to the next process, with adjustable stretching spacing.

Online coating device

Add chemical coating equipment between longitudinal and transverse stretching to meet special application needs. Double sided coating is adopted, and the coating method adopts the mold head+wire rod method. The water-based coating liquid is transported into the mold cavity through a high-pressure pump, and sprayed onto the surface of the film through the narrow slit of the mold lip. Then, it is flattened by a wire rod to achieve uniform coating.

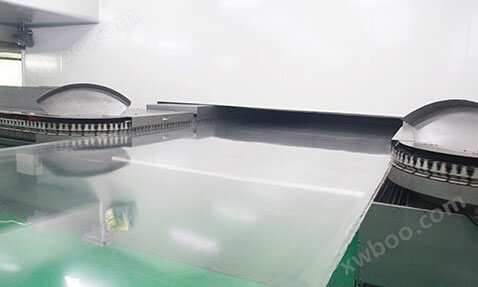

TDO Horizontal Pulling Unit

The TDO transverse pulling unit is mainly composed of the following parts: inlet guide device, inlet deviation adjustment device, guide rail amplitude modulation system, guide rail chain clamp assembly, chain clamp tensioning device, lubrication system, oven system, clamp cooling system, exhaust device, air replenishment device, main transmission system, etc.