VIP member

ACTIS Crack Photography Automatic Extraction System

ACTIS Crack Photography Automatic Extraction System

Product details

Origin: Japan

Introduction: Kuraves Actis produced by KURABO Corporation in Japan is a system that automatically extracts cracks (width and length) from visible images captured by a digital camera. This system can be widely applied to the maintenance and management of buildings such as bridges, tunnels, roads, dams, slopes, and buildings.

Product advantages:

Fully automatic extraction: The software can achieve one click automatic crack extraction function, without the need for manual drawing. With just one touch, the crack position can be automatically determined and the crack width can be given;

Wide measurement range: using internationally leading technology, single shot photography

It can achieve the detection of cracks within a range of 3 meters by 4 meters of the structure.

Fast detection speed: A single person can complete a large area of 2000 square meters (7.5 hours) of detection work in a day, greatly improving the efficiency of surface detection of structures.

Trend monitoring: The software provides a comparison function that can track and compare the development trends of target cracks over multiple time periods;

Strong software functionality: The software has functions such as distortion correction, tilt correction, format correction, arch correction, and image combination, making it more convenient for users to adapt to various shooting conditions;

More intuitive results: measurement results are presented in text, tables CAD、 Various methods such as histograms and crack expansion maps are provided, which are more convenient and intuitive to display in front of users

More convenient to carry: The device mainframe weighs only 4 kilograms, making it easy for one person to carry and measure.

Product Features:

It has functions such as lens correction, tilt correction, image integration, scaling setting, graphic drawing, crack extraction, vectorization/layering/width calculation, length/histogram/DFF output, etc.

1. Image correction

)Distortion correction, solving the deformation caused by lens distortion;

)Tilt correction, correcting images captured at tilt angles;

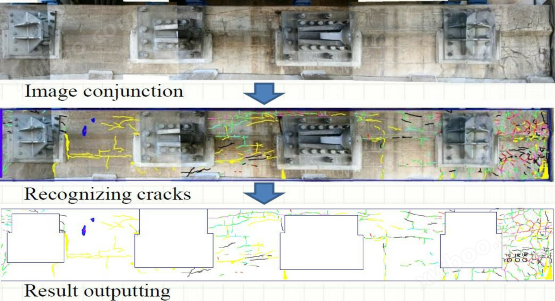

(3.) Image combination, combining multiple images can help track cracks.

2. Automatic crack extraction

After image correction (distortion, tilt), multiple images are stitched together (auxiliary), and cracks are automatically extracted

3. Can output histogram

The vector data for identifying cracks can be output as CSV files, making it easier to intuitively understand the changes and distribution of cracks.

4. Color identification of cracks

Main technical parameters:

Working distance: up to 100 meters

Detection accuracy: 50m (0.05mm) 100m(0.2mm)

Measurement area: Single measurement area of 3m * 4m

Working angle: 360 ° all-round without dead corners

Data storage capacity: 64GB (expandable)

Battery life: 12 hours

Crack extraction method: One click full width extraction

Detection speed: 260 ㎡/h

Applicable objects: Planes, surfaces, cylinders

Output format: CAD, Exelt, TXT, CXV, DFX formats

Output result: Global crack distribution of the structure

Image scaling rate: 7360 * 4912PIX

Online inquiry